| Damascus Steel |

Damascus steel is a hot-forged steel used in Middle Eastern swordmaking from about 1100 to 1700 AD. Damascus swords were of legendary sharpness and strength, and were apocryphally claimed to be able to cut through lesser quality European swords and even rock. The technique used to create original Damascus steel is now a matter of historical conjecture. Many raw materials and the metalsmiths' recipes are no longer available. The foundation for Damascus Steel is Wootz Steel, which originated in India and Sri Lanka and later spread to Persia. From the 3rd century to 17th century, India was shipping steel ingots to the Middle East for use in Damascus Steel.

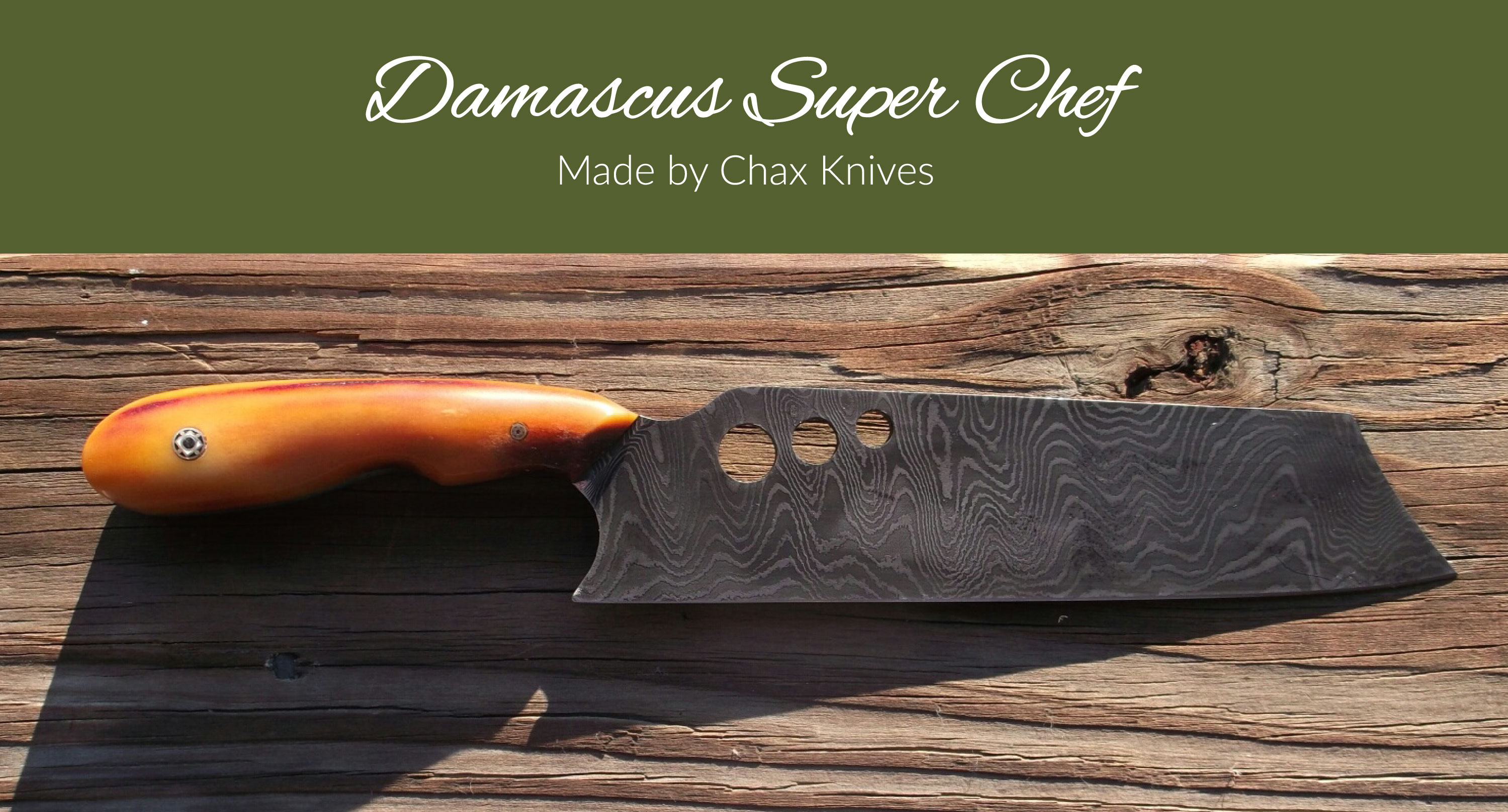

The general term "Damascus" refers to metal with a visible grain pattern, sometimes with a texture. Modern Damascus is a lamination of folded steels selected with cosmetic qualities, with grinding and polishing specifically to expose the layers. True Damascus patterns are formed when carbon trace elements form visible swirls in the steel mix. These elements change properties when the steel is work hardened (forged), creating the patterns.